What can Hebel AAC be used for?

Hebel AAC is ideal for residential, apartment and commercial applications. It’s versatility and lightweight handling make it an ideal material to work with

| External Walls | Corridor walls | Floors |

| Internal Walls | Shaft walls | Fire walls |

| Intertenancy and party walls | Service walls | Acoustic sound barriers |

| Zero boundary walls | High rise facades | |

| Fences | Balcony blades |

The history of AAC

CSR Hebel is the only manufacturer of AAC in Australia. The company has been manufacturing Hebel since 1990. Hebel’s reputation has stood the test of time, and today continues to lead the way in fast, economic, and sustainable building solutions.

Performance and benefits of AAC

Autoclaved Aerated Concrete (AAC) is a high-performance, versatile building material known for its lightweight composition, strength, and excellent thermal and acoustic insulation. Its sustainability credentials include reduced raw material usage and energy efficiency, making it an eco-friendly choice for modern construction. With its ease of installation and adaptability to various designs, AAC is a durable and practical solution for residential, commercial, and industrial projects.

-

Strong & solid

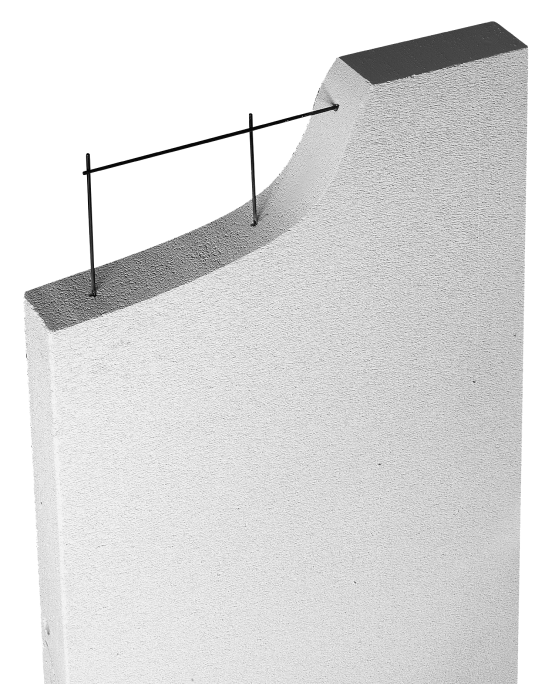

Hebel panels are high-performance products containing steel reinforcement for added strength with an anti-corrosion layer on the steel for maximum durability.

-

Quality & speed

Building with Hebel can mean faster construction times, without sacrificing on quality.

-

Fire resistant

Hebel is a non-combustible building material and renowned for its fire resistant properties.

-

Design versatility

With Hebel the design possibilities are endless with a wide range of aesthetic coating options.

Find out how Hebel AAC is made

Similar to regular concrete, AAC is made from water, sand, lime, and cement. However, when making AAC a special expansion agent is added to the mix to form a slurry. The slurry is then poured into a mould containing steel reinforcing mesh that has a corrosion resistant coating. Chemical reactions occur between the ingredients to form hydrogen bubbles which cause the slurry to expand, rise and aerate. When semi-cured, it is released from the mould and cut to size. Then it is steam pressure cooked in an autoclave oven to harden.

Reinforced AAC Standards (AS 5146:2015 Parts 1-3)

In 2015 Standards Australia approved and published a set of standards for reinforced AAC, known as AS 5146:2015 (Parts 1-3). These standards help guide the use of reinforced AAC in designs and construction within Australia.

AS 5146 (Parts1-3) were referenced in the Building Code of Australia in May 2016, making Reinforced AAC a ‘deemed to satisfy’ (DTS) building material. This means that if builders and installers construct a building using the details provided in AS 5146, (Part 3), it should make for easier certification of the building by the relevant building certification authority. All Hebel products and systems are compliant with AS 5146 (Parts 1-3).

Frequently asked questions

How is Aerated Autoclaved Concrete used in buildings?

Hebel PowerBlock AAC blocks are laid like bricks and are used for load bearing walls up to three stories. They replace double brick walls with the benefits of construction speed and three times better thermal resistance.

With lightweight frame construction on residential buildings 50mm and 75mm thick reinforced autoclaved aerated concrete cladding is used in place of brick veneer construction. Where products like PowerPanelXL can be installed 60% faster than bricks. For residential joist flooring, PowerFloor is used as a subfloor that is more solid under foot than particle board flooring. PowerFloor+ commercial flooring panels can span up to 5.85 metres and do not require floor joists.

In commercial and industrial applications thick 100mm to 300mm thick panels are installed vertically or horizontally for external walls, shaft walls, fire walls and acoustic walls. The panels can provide fire and acoustic performance to meet the National Construction Code requirements.

Why is Hebel Autoclaved Aerated Concrete (AAC) preferred over other building products?

Hebel products and systems are designed and developed in Australia by CSR Building Products and are rigorously tested and assessed to ensure products are high quality and that building systems work efficiently to meet building and compliance standards easily.

Builders, designers, certifiers and homeowners enjoy the benefits of Hebel AAC such as:

– Proven & compliant: designed and manufactured to Australian Standards.

– Strong & solid: made from concrete and steel reinforcing.

– Quality & speed: installing one standard Hebel panel eliminates laying 75 standard bricks.

– Energy efficient: good thermal performance helps keep homes cool in summer and warm in winter.

– Noise reduction: good acoustic properties reduce noise transmission.

Fire resistant: non-combustible and achieves Fire Resistance Levels from 60 to 240 minutes.

Where is Hebel AAC made?

Hebel AAC includes a range of Australian made and imported products. Hebel imported products are manufactured to Australian standards and undergo the same rigorous quality testing.

Find a...

We have a network of suppliers ready to help you get your project up and running.